Mochini oa ho Etsa Li-Tissue Pampiri oa Lebelo le Phahameng ka Botlalo o Iketsang ka Botlalo o Iketsang ka Botlalo o Monyenyane oa ho Etsa Li-Tissue tsa Pampiri ea ho Etsa Theko Chaena

Mochini ona oa ho kgutlisa pampiri ea ntloana o ka kgutlisa moqolo o moholo oa pampiri ea ntloana ka bophara bo fapaneng bo bonyenyane ntle le ho fetola bophara ba oona. Bophara le ho tiea ha meqolo ea ntloana e felileng ho ka fetoloa habonolo ka ho fetola litlhophiso phanele ea taolo, 'me meqolo ea pampiri e hlahisoang e se e loketse ho seha.

Sesebelisoa sena sa ho kgutlisa pampiri ya ntloana se sebedisa taolo ya lebelo le sa fetoheng kgato ya AC, e ka sebetsang ka botsitso ha bareki ba fetola lebelo la yona.

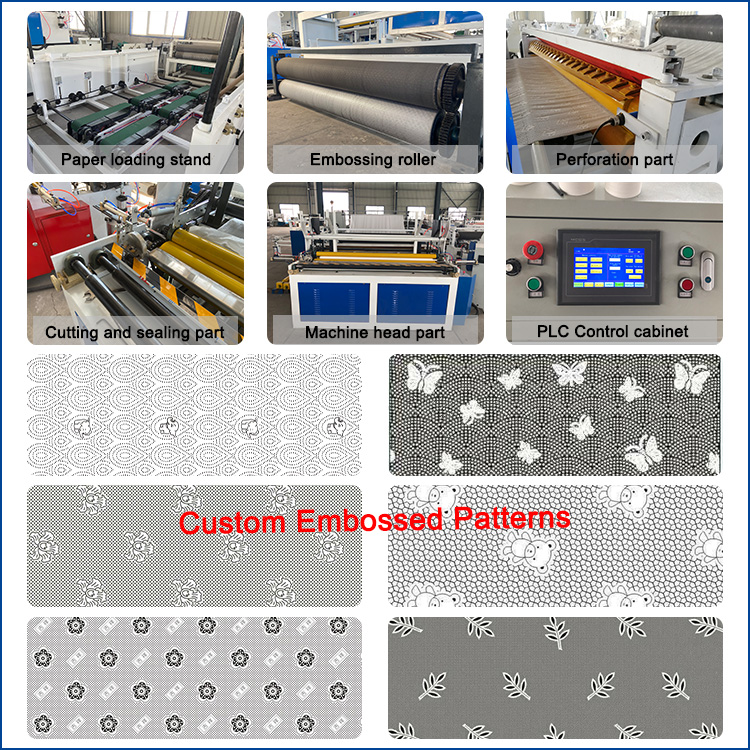

Mochini ona o na le sistimi ea PLC le phanele ea taolo ea Human Machine Interface e le hore motho a le mong a ka e sebelisa habonolo haholo. Ke mochini o loketseng fektheri e nyane ea ho etsa lihlahisoa tsa pampiri ea ntloana.

| Mohlala | YB-1880 | YB-3000 |

| Bophara ba moqolo o moholo (mm) | ≦2200mm | ≦3000mm |

| Boholo ba pampiri e tala | 76.2mm | |

| Bophara ba sehlahisoa se felileng | 90-250mm (Boholo bo bong bo lokelang ho hlalosoa) | |

| Boholo ba mantlha ba sehlahisoa se felileng | Φ 32-50mm | |

| Sebaka sa ho phunyeha | 100-150mm (Boholo bo bong bo lokelang ho hlalosoa) | |

| Ho kuta le ho tiisa mohatla | sehiloeng ka kakaretso, mohatla o koetsoe hantle le ka mokhoa o tšepahalang; Tanka ea polokelo e tla tšoara sekhomaretsi | |

| Ho khanna ka sehloohong | Taolo ea lebelo la phetoho ea maqhubu 7.5-15KW 380V,50HZ | |

| Phaephe ea mantlha: | Ho kenya ka bohona mantlha | |

| Sekontiri sa lesoba | Mahare a 6, 110mm | |

| Ho seta ha liparamente | HMI | |

| Lebelo la mochini | 0-300m/motsotso | |

| Yuniti ea ho khabisa | Tšepe ho tloha ho rabara/tšepe ho isa ho tšepe/tšepe ho isa ho ulu | |

| Sistimi ea moea | Kompresa ea moea ea 3HP, khatello e tlase ea 5kg/cm2pa (e fanoa ke mosebelisi) | |

| Ho khanna ka mechini | Ho khanna ka lebokose la gear le se nang mehato | |

| Boima ba 'mele | 3T | 4T |

| Yuniti ea ho Lamination | E ka odarwa | |

Ho fepa ka boiketsetso ka li-roller tse 'ne → ho fetisa ka mokhoa o ts'oanang → ho khabisa → ho otla → ho thiba ka boiketsetso → ho seha → ho paka → ho tiisa.

1. Ho kgutlisa morao---Morero o ka sehloohong wa mochini wa ho kgutlisa pampiri ya ntloana ke ho sebetsana le pampiri e kgolo ya mokoti hore e be moqolo o molelele wa pampiri ya ntloana.

2. Seha pampiri---Sekhechana se selelele sa pampiri ea ntloana se sehiloeng ke motho ea sehang pampiri se sehoa hore e be lihlahisoa tse sa phethoang hantle tse bolelele ba sona

e hlokoang ke moreki.

3. Sephutheloana---Sephutheloana se ka pakoa ka mochining oa ho paka kapa sa phutheloa ka letsoho, 'me lihlahisoa tse seng li felile tsa pampiri ea ntloana li pakoa le ho koaloa ka mochini oa ho tiisa.

1. Ho sebedisa khomphutha ya PLC ho hlophisa pampiri e qetilweng tshebetsong ya ho kgutlisa morao ho fihlella ho tiya le ho hlepha ha ho tiya ho fapaneng ho rarolla ho hlepha ha sehlahiswa se qetilweng ka lebaka la polokelo ya nako e telele.

2. Mochini o kgutlisang morao ka boiketsetso o ka kgetha motswako wa ho kgomaretsa o nang le mahlakore a mabedi, o ka etsang hore pampiri e be bonolo ho feta ho qomatsa o nang le mahlakore a le mong, phello ya dihlahiswa tse fedisitsweng tse nang le mahlakore a mabedi e tsitsitse, mme lera le leng le le leng la pampiri ha le hasane ha le sebediswa, haholo-holo le loketse ho sebetswa.

3. Mochini o hlomelitsoe ka ho sebetsana le pampiri ea ntloana e sa reroang, e tiileng, e ka fetohang hang-hang pakeng tsa lihlahisoa, 'me e ka boela ea khethoa ho latela litlhoko tsa mosebelisi.

4. Ho kuta ka boiketsetso, ho fafatsa ka sekhomaretsi, ho kwala le ho shafting ho phethelwa ka tsela e tsamaellanang, e le hore ho se ke ha eba le tahlehelo ya pampiri ha pampiri ya rolo e sehwa ka hara saga ya band mme e pakwa, e leng se ntlafatsang haholo bokgoni ba tlhahiso le boleng ba sehlahiswa se fedileng. Ho bonolo ho e nolofalletsa.

5. Phepelo ea lebanta la pneumatic, reel e habeli le axis e 'ngoe le e 'ngoe ea pampiri ea pele li na le mokhoa o ikemetseng oa ho lokisa tsitsipano

-

Mochini oa ho etsa pampiri ea tissue ea napkin o nang le 1/4

-

Mochini oa ho etsa pampiri ea lehe la Bamboo o mocha ...

-

Mochini oa ho itšeha oa sehlopha sa othomathike bakeng sa othomathike ...

-

Nyenyane tlhahiso ea pampiri e lahloang e iketsang ...

-

Pipe ea Mochini oa Pipe ea Spiral Paper Core e Iketsang ka Bophara ...

-

Mochini oa ho Etsa Pampiri ea Lithishu Sete e Felletseng ...