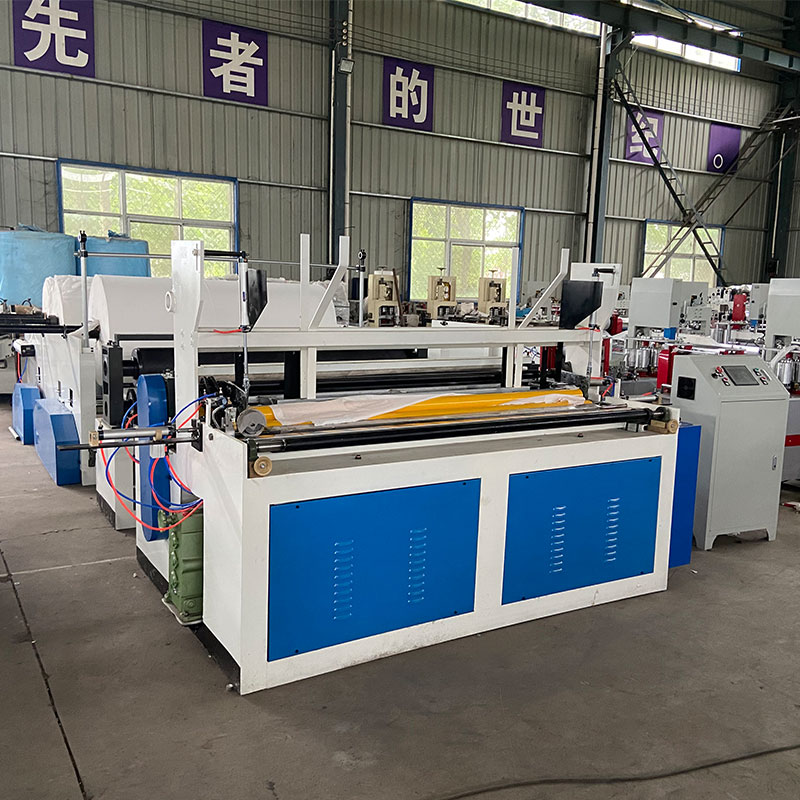

Mochini o kgutlisang pampiri ya ntloana o ka kgutlisa moqolo o moholo wa ntloana hore e be moqolo o monyane o nang le bophara bo fapaneng bo bonyenyane ho ya ka tlhoko. Ha o fetole bophara ba moqolo o moholo, ebe moqolo o monyane wa ntloana o ka sehwa ka moqolo o monyane wa pampiri ya ntloana o boholo bo fapaneng. Hangata o sebediswa le mochini o sehang sa lebanta le mochini o pakang le o tiisang moqolo wa pampiri.

Mochini ona o sebelisa theknoloji e ncha ea machaba ea mananeo a khomphutha ea PLC (tsamaiso e ka ntlafatsoa), taolo ea maqhubu, brake ea elektroniki e iketsang. Sistimi ea ts'ebetso ea sebopeho sa motho le mochini oa ho ama e sebelisa sistimi ea ho etsa ho khutlela morao e se nang motheo. Ts'ebeliso ea lenaneo la PLC theknoloji ea ho etsa kholomo ea moea e fihlella litšobotsi tsa ho khutlela morao kapele le ho bopa hantle haholoanyane.

| Lebitso la sehlahisoa | Mochini oa ho Khutlisa Pampiri ea Ntloana ka Boiketsetso |

| Mohlala oa mochini | YB-1575/1880/2100/2400/2800/3000/S3000 |

| Bophara ba moqolo oa pampiri ea motheo | 1200mm (Ka kopo hlalosa) |

| Bophara ba mantlha ba moqolo o moholo | 76mm (Ka kopo hlalosa) |

| Tebele | Thipa e 2-4, mola oa ho seha o spiral |

| Letoto la taolo | Taolo ea PLC, taolo ea lebelo la maqhubu a feto-fetohang, ts'ebetso ea skrine ea ho ama |

| Mefuta ea lihlahisoa | pampiri ea mantlha, pampiri e seng ea mantlha |

| Phaephe ea ho theola | ka letsoho le ka boiketsetso (ha ho hlokahale) |

| Lebelo la ho sebetsa | 80-280 m/motsotso |

| Matla | 220V/380V 50HZ |

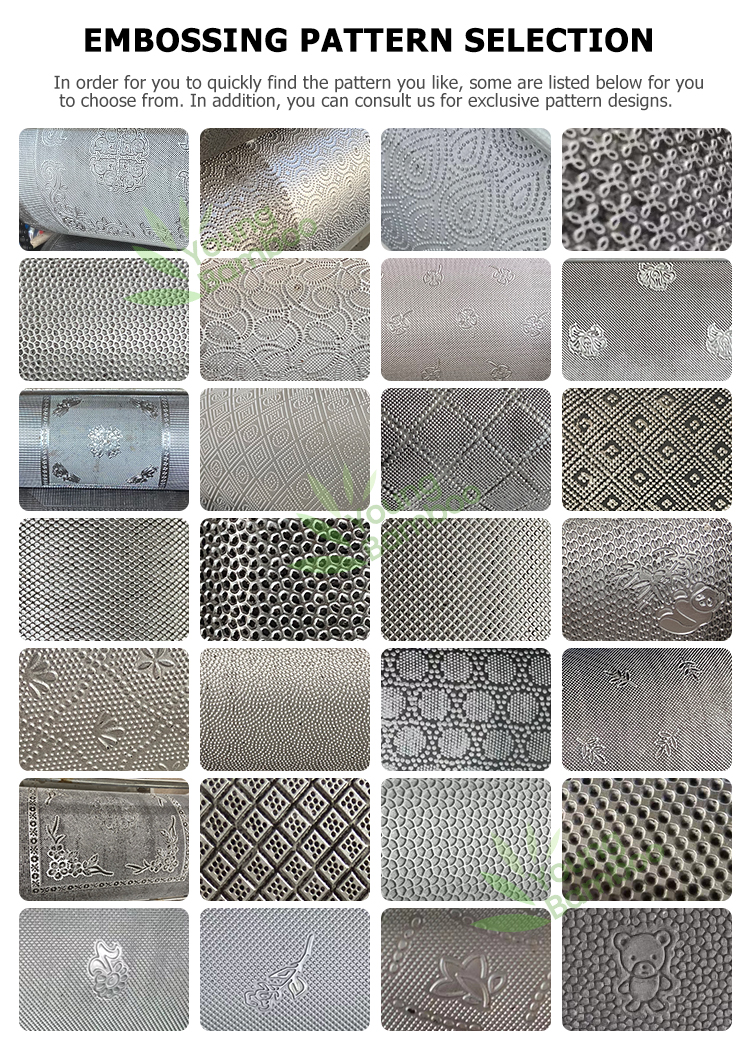

| Ho khabisa ka mongolo o motsho | Ho khabisa ka bonngoe, ho khabisa habeli |

| Ho qalisoa ha sehlahisoa se felileng | Othomathiki |

Pampiri ea ntloana Sekoahelo sa silindara se benyang;rolara e benyang

Mohala oa tlhahiso oa mochini oa ho khutlisa pampiri ea ntloana o iketsang ka semi-automatic o na le likarolo tse tharo

Sa pele【sebelisa mochini o khutlisetsang pampiri ea ntloana morao ho khutlisetsa moqolo o moholo oa pampiri moqolong o monyenyane oa pampiri o bophara bo reriloeng】

Ebe o sebedisa ho seha moqolo ka letsoho ho etsa moqolo o monyane wa pampiri o bolelele ba sepheo. Moqolo

Qetellong,【sebelisa mochini o koalang o pholisitsoeng ka metsi kapa mochini o mong oa ho paka ho koala moqolo oa pampiri】

Ha ho bapisoa le mela ea tlhahiso ea pampiri ea ntloana e iketsang ka bo eona

Molemo oa mohala oa tlhahiso ea pampiri ea ntloana o iketsang ka botlalo ke ho eketsa tlhahiso le ho boloka basebetsi

Sa pele【sebelisa mochini o khutlisetsang pampiri ea ntloana morao ho khutlisetsa moqolo o moholo oa pampiri moqolong o monyenyane oa pampiri o bophara bo reriloeng】

Ebe moqolo o monyenyane oa pampiri ka mor'a ho o kgutlisa morao o tla feta ka mochining o itšehang oa ho seha pampiri ea ntloana ka boiketsetso ebe o o seha ka boiketsetso hore e be moqolo o monyenyane oa pampiri ea bolelele bo reriloeng.

Qetellong, 【meqolo e menyenyane ea pampiri ka mor'a ho seha e tla feta ka har'a lebanta la ho tsamaisa thepa 'me e isoe mochining oa ho paka pampiri ea ntloana o iketsang bakeng sa ho paka. Bongata bo fapaneng ba meqolo ea pampiri bo ka pakoa ho latela tlhoko.】

1. Ho sebedisa khomphutha ya PLC ho hlophisa pampiri e qetilweng tshebetsong ya ho kgutlisa morao ho fihlella ho tiya le ho hlepha ha ho tiya ho fapaneng ho rarolla ho hlepha ha sehlahiswa se qetilweng ka lebaka la polokelo ya nako e telele.

2. Mochini o kgutlisang morao ka boiketsetso o ka kgetha motswako wa ho kgomaretsa o nang le mahlakore a mabedi, o ka etsang hore pampiri e be bonolo ho feta ho qomatsa o nang le mahlakore a le mong, phello ya dihlahiswa tse fedisitsweng tse nang le mahlakore a mabedi e tsitsitse, mme lera le leng le le leng la pampiri ha le hasane ha le sebediswa, haholo-holo le loketse ho sebetswa.

3. Mochini o hlomelitsoe ka ho sebetsana le pampiri ea ntloana e sa reroang, e tiileng, e ka fetohang hang-hang pakeng tsa lihlahisoa, 'me e ka boela ea khethoa ho latela litlhoko tsa mosebelisi.

4. Ho kuta ka boiketsetso, ho fafatsa ka sekhomaretsi, ho kwala le ho shafting ho phethelwa ka tsela e tsamaellanang, e le hore ho se ke ha eba le tahlehelo ya pampiri ha pampiri ya rolo e sehwa ka hara saga ya band mme e pakwa, e leng se ntlafatsang haholo bokgoni ba tlhahiso le boleng ba sehlahiswa se fedileng. Ho bonolo ho e nolofalletsa.

5. Phepelo ea lebanta la pneumatic, reel e habeli le axis e 'ngoe le e 'ngoe ea pampiri ea pele li na le mokhoa o ikemetseng oa ho lokisa tsitsipano

-

Mochini o felletseng oa ho paka pampiri ea ntloana o iketsang ...

-

YB-2400 Pampiri ea ntloana e iketsang ea khoebo e nyane ...

-

YB-1*3 mochini o etsang terei ea mahe 1000pcs/h bakeng sa bu ...

-

Mochini oa ho seha pampiri oa letsoho oa sehlopha sa letsoho bakeng sa halofo ea ...

-

Mochini o felletseng oa ho phunya o moholo o iketsang o moholo ...

-

YB-4 lane bonolo thaole sefahleho dinama tse nyenyane tse etsang pampiri ...