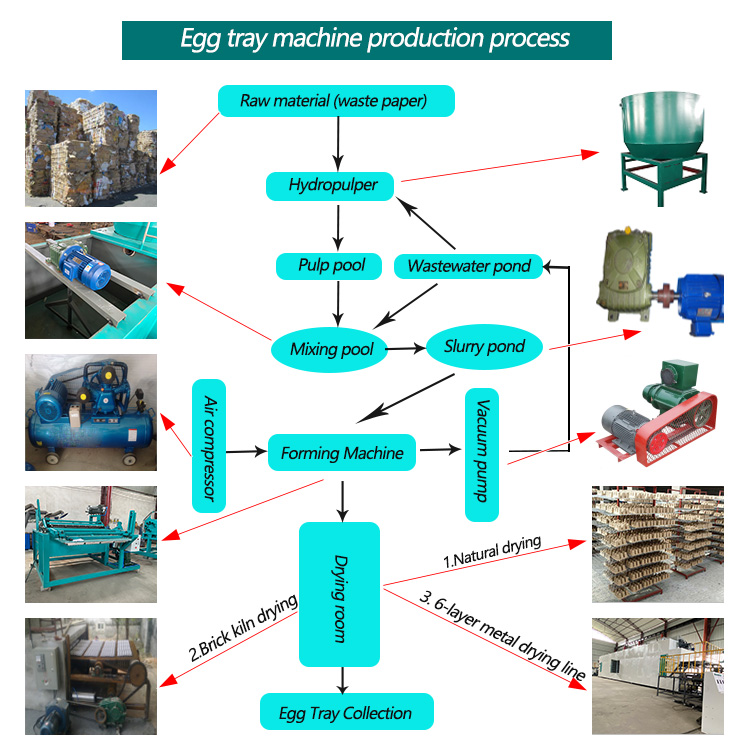

Mohala oa tlhahiso ea terei ea mahe ea Young Bamboo pulp molding o iketsang o sebelisa pampiri e litšila e le thepa e tala, e nang le mehloli e mengata le litheko tse tlase, 'me ke nts'etsopele e felletseng le ts'ebeliso ea litšila. Metsi a sebelisoang ts'ebetsong ea tlhahiso a koetsoe 'me a sebelisoa hape, ha ho na metsi a litšila kapa khase e litšila e ntšitsoeng. Kamora hore lihlahisoa tsa pulp molding li sebelisoe, litšila li ka sebelisoa hape joalo ka pampiri e tloaelehileng. Esita le haeba li lahliloe tikolohong ea tlhaho, ho bonolo ho bola le ho bola hore e be pampiri e tloaelehileng. Lintho tsa tlhaho ke lihlahisoa tse mosa tikolohong ka botlalo. Pampiri e litšila e eketsoa ho pulper 'me metsi a romeloa tankeng ea polokelo. Pulp e ka tankeng ea polokelo e fetisetsoa ka ho lekana tankeng ea phepelo ka motswako. Pulp e ka tankeng ea phepelo e hlohlelletsoa ho fihlela khatellong e itseng 'me e romeloa mochining oa ho bopa. Mochini oa ho bopa o hlahisa terei ea mahe ho ea lebanta la Conveyor. Lebanta la conveyor le feta ka har'a mohala oa ho omisa terei ea mahe, 'me qetellong ea bokelloa le ho pakoa. Ho feta moo, pompo ea vacuum e ka pompa metsi a sa sebelisoang mochining oa ho bopa ho ea tankeng ea metsi a ka morao. Tanka ea metsi a ka morao e ka isa metsi ho pulper le tankeng ea polokelo ea pulp, 'me metsi a ka sebelisoa hape.

Lisebelisoa tse tala li tsoa haholo-holo libotong tse fapaneng tsa pulp tse kang pulp ea lehlaka, pulp ea joang, slurry, pulp ea lehlaka le pulp ea lehong, le paperboard ea litšila, pampiri ea lebokose la pampiri ea litšila, pampiri e tšoeu ea litšila, pulp ea mohatla oa mochini oa pampiri, jj. Pampiri ea litšila, e fumanehang haholo 'me e bonolo ho e bokella. Mosebetsi ea hlokahalang ke batho ba 5/sehlopha: motho a le mong sebakeng sa pulping, motho a le mong sebakeng sa ho bopa, batho ba 2 ka kariking, le motho a le mong ka har'a sephutheloana.

| Mohlala oa Mochini | 1*3 | 1*4 | 3*4 | 4*4 | 4*8 | 5*8 | 5*12 | 6*8 |

| Tlhahiso (p/h) | 1000 | 1500 | 2500 | 3000 | 4000-4500 | 5000-6000 | 6000-6500 | 7000 |

| Pampiri e senyehileng (kg/h) | 80 | 120 | 160 | 240 | 320 | 400 | 480 | 560 |

| Metsi (kg/h) | 160 | 240 | 320 | 480 | 600 | 750 | 900 | 1050 |

| Motlakase (kw/h) | 36 | 37 | 58 | 78 | 80 | 85 | 90 | 100 |

| Sebaka sa Thupelo | 45 | 80 | 80 | 100 | 100 | 140 | 180 | 250 |

| Sebaka sa ho Omisa | Ha ho hlokahale | 216 | 216 | 216 | 216 | 238 | 260 | 300 |

2. Matla a bolela likarolo tse ka sehloohong, eseng ho kenyelletsa mohala oa dryer

3. Tekanyo eohle ea tšebeliso ea mafura e baloa ka 60%

4. bolelele ba mohala o le mong oa dryer ke limithara tse 42-45, lera le habeli ke limithara tse 22-25, lera le lengata le ka boloka sebaka sa mosebetsi

-

YB-1*3 mochini o etsang terei ea mahe 1000pcs/h bakeng sa bu ...

-

Mohala oa tlhahiso ea pampiri ea makhasi a lehe a iketsang / ...

-

Mochini oa ho etsa pampiri ea lehe la Bamboo o mocha ...

-

Jarolla ka ho iketsa pampiri litšila makhasi a lehe tereing ho etsa mach ...

-

1*4 litšila tsa pampiri ea pampiri e omisang terei ea mahe Ma ...

-

Mochini oa ho Etsa Mahe a Tereiti ea Lehe bakeng sa Nyenyane ...