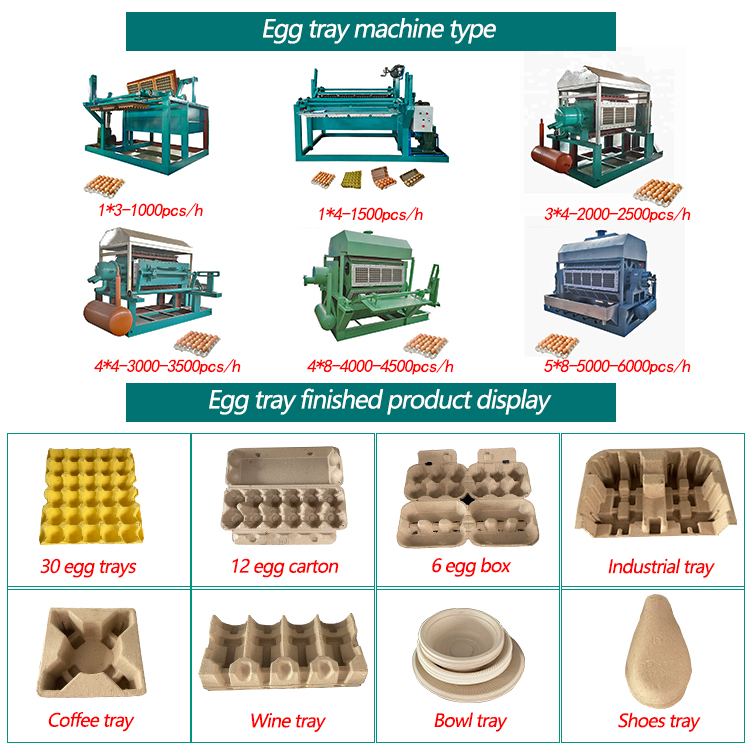

1. Mohala oa tlhahiso ea ho bopa makhasi o tsejoa e le mohala oa terei ea mahe bakeng sa ho sebelisoa haholo ho hlahiseng terei ea mahe.

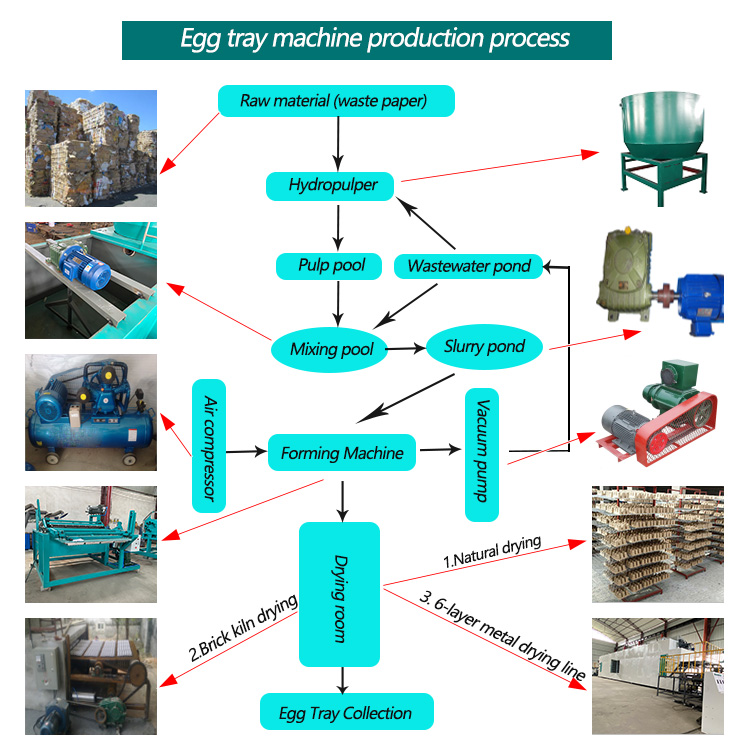

2. Mohala oa tlhahiso ea ho bopa makhasi, o sebelisang pampiri e senyehileng, khateboto, thepa e setseng ea mochini oa pampiri, ka pulper ea hydraulic, motsoako o etsang pulp e itseng e teteaneng, 'me makhasi a monngoa ke vacuum ea bōpeho e khethehileng ea tšepe hore e be lihlahisoa tse metsi, ka ho omisa, le ho bopa hore e be lihlahisoa tse felileng.

3.Ts'ebetso ea Mohala oa ho Bopa Makhasi e sebelisa metsi a sebelisitsoeng hape 'me ha e lebise tšilafalong ea metsi kapa moea. Lihlahisoa tse phethiloeng tsa ho paka li ka sebelisoa hape kamora ho sebelisoa polokelong, lipalangoangng le thekisong. Kamora ho li pshatla, ho bonolo ho li bolisa e le pampiri, leha li ka lahleloa tikolohong ea tlhaho.

4. Mela ea tlhahiso ea ho bopa makhasi a iketsang e ka ba tlhahiso e kholo ea setshelo se fapaneng sa lijo, terei ea mahe, mabokose a lijo tsa motšehare le tse ling.

| Mohlala oa Mochini | 1*3/1*4 | 3*4/4*4 | 4*8/5*8 | 5*12/6*8 |

| Tlhahiso (p/h) | 1000-1500 | 2500-3000 | 4000-6000 | 6000-7000 |

| Pampiri e senyehileng (kg/h) | 80-120 | 160-240 | 320-400 | 480-560 |

| Metsi (kg/h) | 160-240 | 320-480 | 600-750 | 900-1050 |

| Motlakase (kw/h) | 36-37 | 58-78 | 80-85 | 90-100 |

| Sebaka sa Thupelo | 45-80 | 80-100 | 100-140 | 180-250 |

| Sebaka sa ho Omisa | Ha ho hlokahale | 216 | 216-238 | 260-300 |

Koloi ea servo e sebetsang hantle haholo, e sebetsang hantle haholo le e bolokang matla.

1, Sebelisa mochini o fokotsang lebelo o etsang le ho fetisetsa motlakase oa servo ho netefatsa hore o sebetsa ka potlako le ka mokhoa o motle.

2, Sebelisa encoder e feletseng ho fihlela tokiso e nepahetseng.

3, Tšebeliso ea sebopeho sa lesale la ho lahla boronse se sa fetoheng le se matla se loketse haholoanyane ts'ebetso ea ho tlosa metsi sehlahisoa.

4, Tšebeliso ea sebopeho sa mechini ho netefatsa hore hlobo e koala mahlakoreng ka bobeli ka ho lekana.

5, Bokgoni bo boholo; Metsi a tlase; Boloka litšenyehelo tsa ho omisa.

1. Sistimi ea ho phunya

2. Sistimi ea ho theha

3. Sistimi ea ho omisa

(3) Mohala o mocha oa ho omisa oa mekhahlelo e mengata: Mohala oa ho omisa oa tšepe oa mekhahlelo e 6 o ka boloka matla a fetang 30%

4. Sehlahisoa se fedileng se thusang sephutheloana

(2) Mohlahisi

(3) Sepalami sa phetisetso

-

Mochini oa ho etsa pampiri ea lehe la Bamboo o mocha ...

-

Matlakala Pampiri ea ho Sebelisa Bocha Egg Carton Box Egg Tray M ...

-

YB-1*3 mochini o etsang terei ea mahe 1000pcs/h bakeng sa bu ...

-

Mohala oa tlhahiso ea pampiri ea makhasi a lehe a iketsang / ...

-

Mochini oa ho Etsa Mahe a Tereiti ea Lehe bakeng sa Nyenyane ...

-

Jarolla ka ho iketsa pampiri litšila makhasi a lehe tereing ho etsa mach ...